Thermoplastic Elastomers (TPE)

Thermoplastic Elastomers (TPE) combine the processing properties of thermoplastics and the physical properties if elastomers. The characteristics of TPE are very similar to those of rubber: They are soft, flexible and elastic.

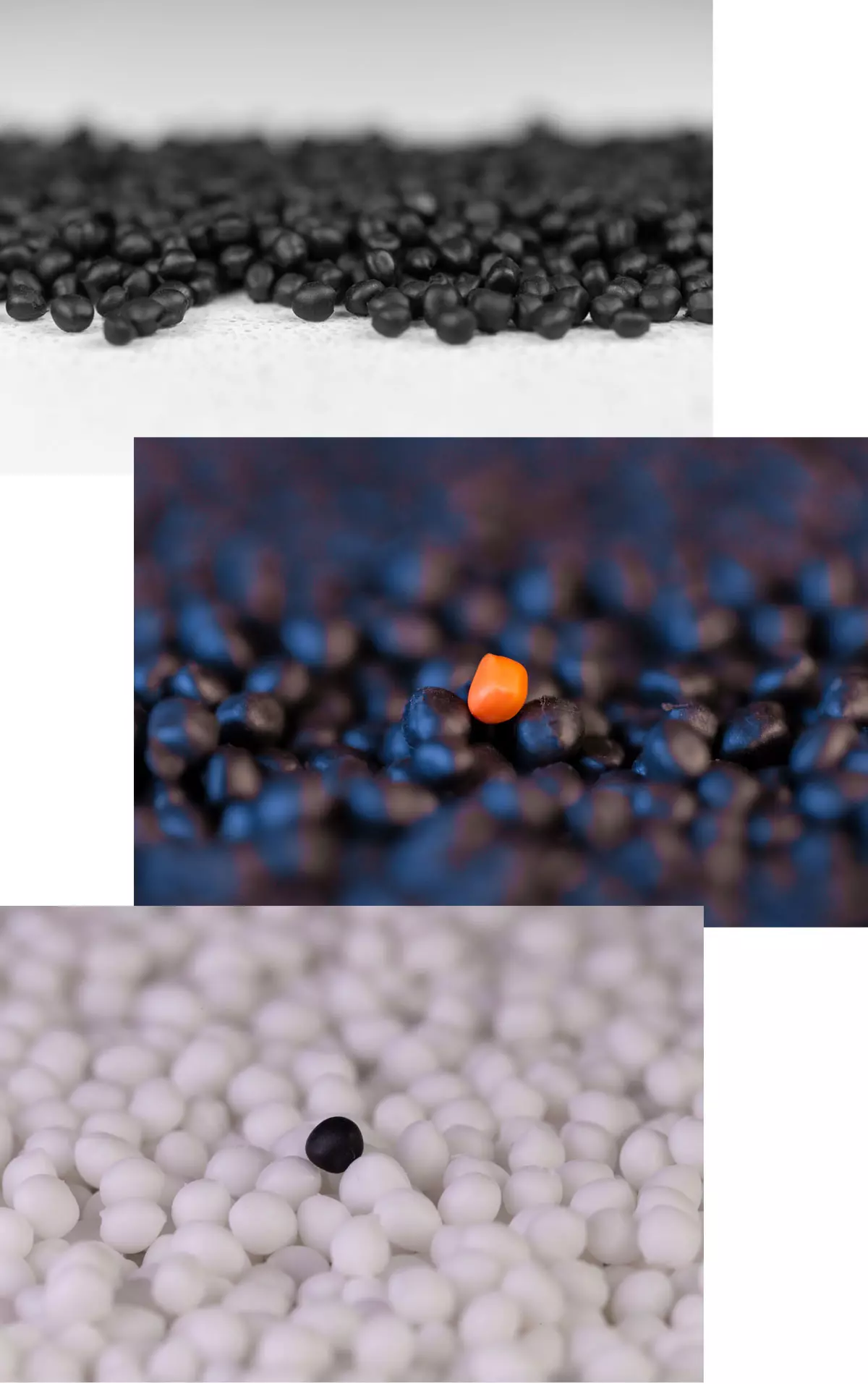

At the same time, the thermoplastic phase causes the material to be processable on standard plastic processing equipment for injection molding, extrusion, blow molding, etc. Our products are completely recyclable.

Types of Thermoplastic Elastomers

Three categories of thermoplastic elastomers are differentiated according to their composition:

Styrene-block-copolymer-based TPEs are commonly referred to as TPE-S. TPE-S are typically based on SEBS, SBS, and SEPS. SBS compounds are used in applications with low requirements for UV-stability and thermal strength. SEBS compounds are weather-resistant and possess high temperature resistance.

TPVs, Thermoplastic Vulcanizates or Vulcanized Thermoplastic Elastomers, constitute a specialized group within TPE. They contain an elastomer phase (dynamically vulcanized EPDM), distributed in a polyolefin phase, thus granting these materials rubber-like properties. These compounds have excellent compression set, high elasticity, and are resistant to chemicals and oils. Their temperature resistance is also outstanding.

TPO, Thermoplastic Olefin blends, are a group of polyolefin (polypropylene)-based and EPR (Ethylene-Propylene-Rubber) modified compounds, which possess properties of rubber yet are processed like ordinary thermoplastics.